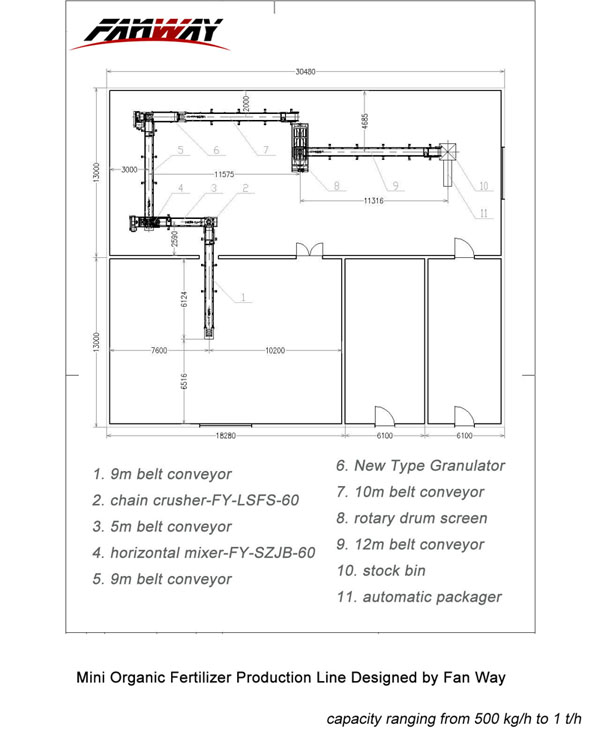

Description of small organic fertilizer production line

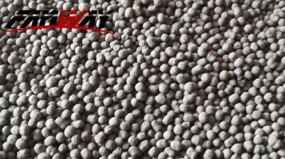

It is the development of Agricultural Machinery Research Institute of the latest high-tech products. And it won the national utility model patent. It is used for granulation of various organic after fermentation of organic, break through the conventional granulating granulation process, raw materials are don’t need to be dried, powder ingredients can produce cylindrical particles, therefore, it can save a lot of energy.

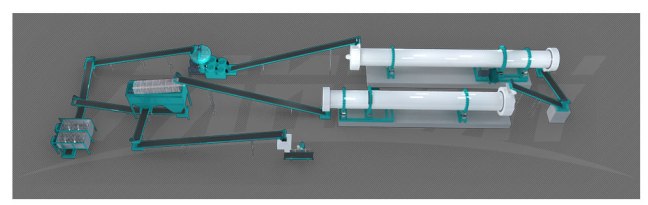

Introduction of organic fertilizer production line

This mini organic fertilizer production line is mainly designed for farming manure, crop straw, sugar and wine residues, paper mill sludge waste residues, urban organic waste and other organic materials.

The standard process of organic fertilizer production line: Fermentation — Crushing — Mixing — Granulating — Drying — Cooling — Screening — Packing

Oragnic Fertilizer Plant Raw material:

1. Agricultural waste: straw, dregs of beans, cotton dregs, rice bran,etc.

2. Animal manure: mixture of poultry litter (PL) and animal waste(AW),such as,

Slaughterhouse Waste,Fish Market,Urine and dung of cattle,Pigs,Sheep,Chicken,

Ducks, Geese,Goat.etc.

3.Industrial waste: wine lees, vinegar residue, manioc waste, sugar scum, furfural residue etc.

4. Home scrap: food waste, bones, the roots and leaves of vegetables, etc.

5. Sludge: the sludge of the river, the sewer, etc.

See more information about organic fertilizer production at:

a. Commercial Organic Fertilizer Production Line Beginning and Construction

b. Commercial Organic Fertilizer Composting and Granulating

c. Medium-scale to Large-scale Organic Fertilizer Production Line for Sale